Why FKM Oil Seals Are Best for Hydraulic Pumps | DMHUI Seal Solutions

Share

Hydraulic pumps are at the core of countless industrial and mobile applications, from heavy construction machinery to agricultural equipment, automotive systems, and industrial presses. These pumps rely on oil seals to prevent leakage, maintain fluid pressure, and protect critical components from contamination. Among all seal materials, FKM oil seals are recognized as one of the most reliable solutions in demanding environments.

In this article, we’ll explore why FKM seals are the preferred choice for hydraulic pumps, how they outperform other seal types, and what benefits they bring in terms of heat resistance, chemical durability, and high-pressure sealing.

What Are FKM Oil Seals?

FKM (fluoroelastomer) is a synthetic rubber material known for its exceptional heat and chemical resistance. First developed in the mid-20th century, FKM has become the go-to material for seals, O-rings, and gaskets used in high-performance industries such as automotive, aerospace, and oil & gas.

When used in hydraulic pump seals, FKM offers unique advantages:

- Thermal stability up to 200–250°C

- Resistance to aggressive fluids such as synthetic oils, fuels, and hydraulic fluids

- Excellent compression set resistance, meaning seals maintain their shape under pressure

- Durability in extreme operating conditions, reducing downtime and replacement costs

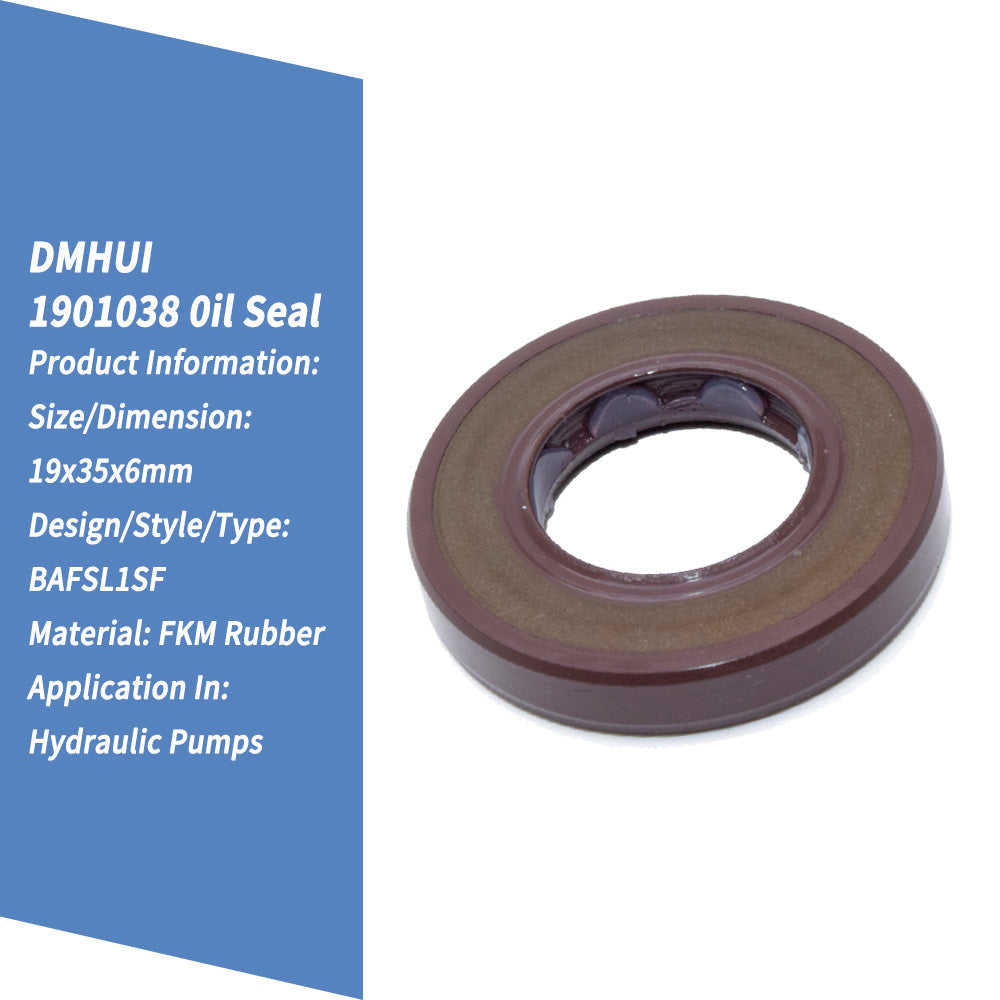

For example, DMHUI’s FKM oil seal 19x35x6mm is specifically engineered for hydraulic pump shafts, delivering long-lasting sealing performance in high-pressure and high-temperature environments.

Why Hydraulic Pumps Need Reliable Seals

Hydraulic pumps function by converting mechanical energy into hydraulic energy, using pressurized fluid to drive machinery. Without effective sealing, several problems can occur:

- Leakage of hydraulic fluid – leading to pressure loss and reduced efficiency

- Contamination ingress – dirt and debris can damage pump components

- Increased wear and tear – due to improper lubrication or fluid escape

- Downtime and costly repairs – resulting from premature seal failure

Therefore, the choice of oil seal is not just about preventing leaks—it directly impacts pump performance, lifespan, and operating costs.

Key Advantages of FKM Oil Seals in Hydraulic Pumps

1. Outstanding Heat Resistance

Hydraulic pumps often operate in environments where friction and high loads generate extreme heat. Standard sealing materials, such as NBR (nitrile rubber), may begin to harden or crack at elevated temperatures.

FKM seals, however, can withstand continuous exposure to 200°C and short-term spikes up to 250°C without losing elasticity. This makes them ideal for:

- Heavy-duty construction equipment

- Agricultural tractors working long hours

- Industrial presses with continuous operation

2. Exceptional Chemical Compatibility

Hydraulic systems frequently use oils with additives, synthetic lubricants, and even aggressive fluids that can quickly degrade standard seals.

FKM seals provide resistance to oils, fuels, solvents, and hydraulic fluids, ensuring:

- No swelling or softening of the seal

- Stable performance in contact with aggressive chemicals

- Extended seal and pump life

This chemical durability is why FKM is often chosen for pumps exposed to aggressive fluids in industrial and mining applications.

3. High-Pressure Sealing Performance

Hydraulic pumps can operate at pressures exceeding hundreds of bar. In such conditions, seals must resist extrusion, deformation, and leakage.

FKM oil seals offer:

- Low compression set, meaning they retain their shape under constant stress

- Tight sealing against shaft surfaces, even in fluctuating pressure environments

- Reduced wear and friction, extending both seal and pump lifespan

4. Extended Service Life and Reduced Maintenance

By combining thermal stability, chemical durability, and high-pressure resilience, FKM seals provide a longer operational lifespan compared to conventional seals.

This translates into:

- Lower maintenance frequency

- Reduced risk of unexpected downtime

- Better overall equipment reliability

For industries where downtime equals lost revenue, these benefits make a measurable difference.

Comparing FKM Oil Seals with Other Materials

| Property | NBR (Nitrile) | ACM (Acrylic) | FKM (Fluoroelastomer) |

|---|---|---|---|

| Heat Resistance | Up to 100°C | Up to 150°C | Up to 250°C |

| Chemical Resistance | Limited | Moderate | Excellent |

| Pressure Performance | Moderate | Good | Excellent |

| Cost | Low | Medium | Higher |

| Service Life | Short–Medium | Medium | Long |

While FKM seals are more expensive than NBR or ACM, their extended service life and reliability in demanding conditions often make them the most cost-effective choice in the long run.

Applications of FKM Oil Seals in Hydraulic Pumps

FKM oil seals are widely used in:

- Construction machinery – excavators, loaders, bulldozers

- Agricultural equipment – tractors, harvesters, sprayers

- Industrial systems – presses, molding machines, machine tools

- Mining equipment – drills, crushers, conveyors

- Automotive hydraulics – power steering, braking systems, hydraulic pumps

In all these sectors, equipment faces high pressure, heavy loads, and harsh environments, where the durability of FKM seals proves critical.

Case Example: DMHUI 19x35x6mm FKM Oil Seal

The DMHUI 19x35x6mm rotary shaft FKM oil seal is designed for hydraulic pump applications requiring:

- Reliable shaft sealing under high pressure

- Resistance to high operating temperatures

- Compatibility with a wide range of hydraulic fluids and lubricants

By integrating this seal into pump systems, operators benefit from longer pump life, fewer seal replacements, and enhanced reliability.

FAQs About FKM Oil Seals for Hydraulic Pumps

1. What is the main advantage of FKM oil seals over NBR seals?

FKM seals offer superior heat and chemical resistance, making them suitable for high-pressure and high-temperature environments where NBR would fail prematurely.

2. Can FKM seals be used in all hydraulic pumps?

Yes, but they are especially recommended for pumps operating under high thermal stress, aggressive fluids, or continuous-duty cycles.

3. Are FKM seals more expensive?

Yes, the material cost is higher than standard NBR seals. However, their longer lifespan and reduced maintenance needs make them more cost-effective over time.

4. What industries benefit most from FKM seals?

Heavy-duty industries such as construction, agriculture, mining, and industrial manufacturing benefit the most from FKM seals due to the harsh operating conditions.

5. How do I choose the right size of FKM oil seal?

Seal selection depends on shaft size, housing dimensions, pressure rating, and operating conditions. For example, DMHUI’s 19x35x6mm FKM oil seal is a popular choice for hydraulic pump applications.

Conclusion

When it comes to hydraulic pump performance, the importance of a reliable sealing solution cannot be overstated. FKM oil seals deliver unmatched advantages in terms of heat resistance, chemical durability, and high-pressure sealing performance.

By choosing high-quality options like DMHUI’s FKM 19x35x6mm oil seal, operators can ensure longer pump life, reduced downtime, and consistent system reliability—a true investment in productivity.

👉 What’s your top challenge in hydraulic sealing? Share your experience and explore how FKM seals can solve your toughest pump challenges.